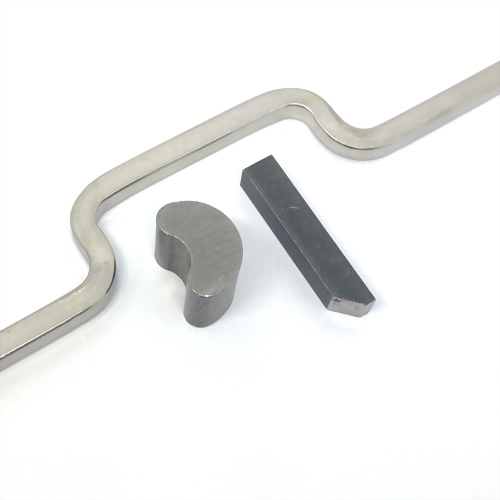

Cold Forging Parts And Others

Description:

This process occurs near room temperature, rather than at higher temperature such as warm and hot forging. Place the workpiece between the two dies and pounding the dies until the metal is formed. Because of the friction created by the process, the temperature of the metal being forged can actually arise to 250° C (482° F).

Specification:

Diameter from M3 to M22

Length from 8mm to 300mm

Material: Carbon Steel, Stainless Steel, Alloy Steel, Copper, Plastic, Super Alloy…etc.

Characteristics:

Advantages of Cold Forging

-Dimensional Accuracy: little or even no excess material left, also the tolerance of the finished diameter could reach about +/-0.3 mm.

-Cost Saving: Mold life is longer than the one for hot forging, which means more stable quality control and better cost control

-More Cost Saving: no need of prior secondary heat treatment & little or no finishing work.

-Decrease of Metal Ductility, but great increase in both yield and tensile strength

Disadvantages of Cold Forging:

-Cannot be comprehensively applied to metal parts – Comparatively, there are more chances to cause crack or to be broken during the production procedures. For example, steel types with carbon content of 0.5% or above cannot be used.

-Available for certain shapes which tend to be more simple and mass-produced, but not suitable for complex part geometries.

Application:

AutomotiveAutomotive (chassis (BMW X5)), Electrified Vehicles, Heavy Equipment, Industrial Components, Appliances, Agriculture (Lawn & Garden), Machinery, Electronics, Energy Industries, Mechanical Engineering, and so on.